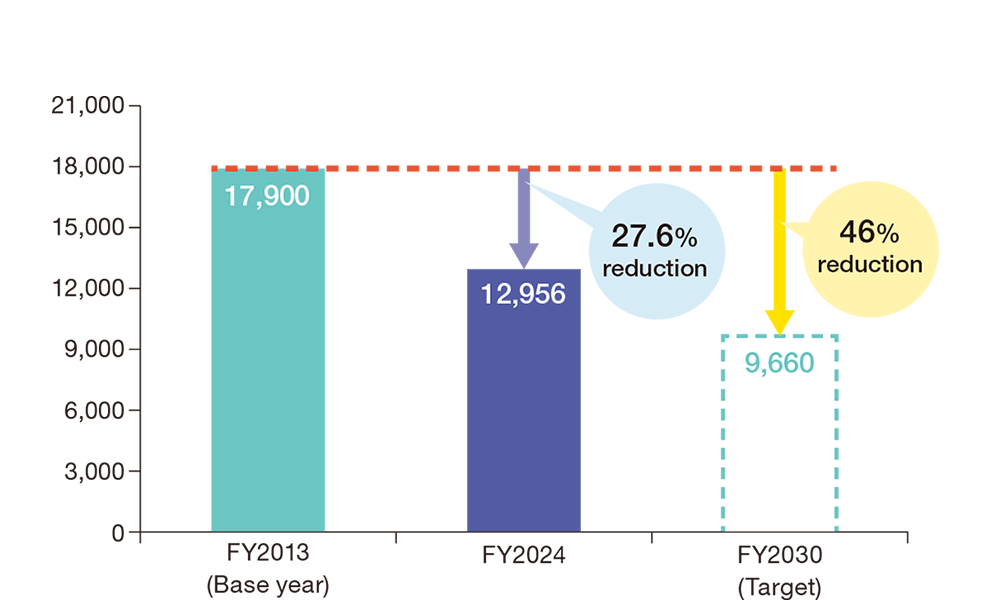

CO2 Emission Reduction Initiatives

Mochida Pharmaceutical Group aims to achieve carbon neutrality by 2050 and is working to reduce CO2 emissions across the entire group through measures such as improving energy efficiency.

Our headquarters building, which commenced operations in September 2022, achieved the highest 5-star rating under the Building-Housing Energy-efficiency Labeling System (BELS) due to its energy-saving design for air conditioning and lighting. It has also obtained "ZEB Ready" certification.

Across all business sites, we are working to reduce the Group's overall CO2 emissions by switching to efficient air conditioning systems, optimizing the operation of chilled water production equipment, and systematically introducing CO2-free electricity. At the Fujieda Site, we commenced operation of a solar power PPA* in February 2025.

Beyond these initiatives, we are systematically working toward achieving our Group's CO2 reduction targets by advancing new solar power generation facilities and the phased adoption of CO2-free electricity.

*PPA (Power Purchase Agreement): A service where a power generator installs solar power generation equipment on the consumer's premises and supplies the generated electricity to the consumer.

[ Trend of CO2 Emissions ](t-CO2)

Sites covered:

Head Office, Gotemba site, Fujieda site and every other business site of Mochida Pharmaceutical Co., Ltd., Head Office Plant of Mochida Pharmaceutical Plant Co., Ltd., and Saitama Plant of Mochida Pharmaceutical Plant Co., Ltd.

CO2 emissions:

Total amount of energy-related CO2 emissions from fuel and electricity consumption

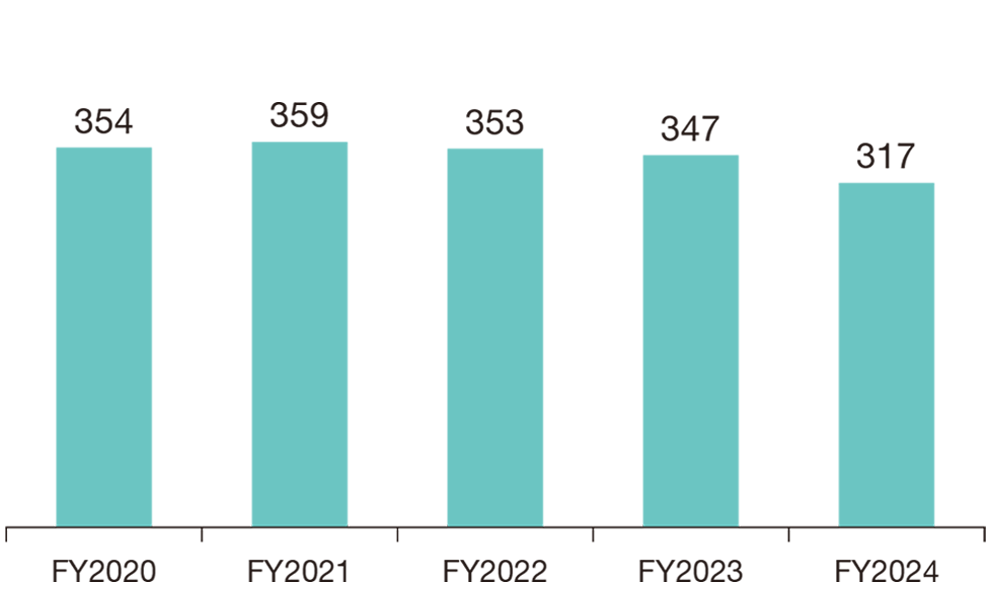

[ Trend of Energy Consumption ] (terajoules)

Sites covered:

Head Office, Gotemba site, Fujieda site and every other business site of Mochida Pharmaceutical Co., Ltd., Head Office Plant of Mochida Pharmaceutical Plant Co., Ltd., and Saitama Plant of Mochida Pharmaceutical Plant Co., Ltd.

Energy consumption:

Total consumption of all types of energy including electricity, fuel oil (until FY2019), gasoline, LNG and city gas

Gas-fired once-through boilers (Head Office Plant of Mochida Pharmaceutical Plant Co., Ltd.)

Heat pumps (Head Office Plant of Mochida Pharmaceutical Plant Co., Ltd.)

Solar Power Generation (Fujieda Site)

Reduction and Recycling of Waste

Mochida Pharmaceutical Group is working on the reduction and recycling of waste generated in its business activities. We promote the 3Rs (Reduce, Reuse, Recycle) and are committed to reducing the amount of waste we generate to 582 tons or lower by FY2030, increasing our waste recycling rate to 98% or higher, and maintaining a plastic waste recycling rate of 65% or higher.

[ Trends of Amount of Waste Generated and Recycling Rate ] (tons)

Sites covered:

Head Office, Gotemba site, Fujieda site and every other business site of Mochida Pharmaceutical Co., Ltd., Head Office Plant of Mochida Pharmaceutical Plant Co., Ltd., and Saitama Plant of Mochida Pharmaceutical Plant Co., Ltd.*

Recycling amount: Total amount of waste generated which was the subject of reuse, material recycling or thermal recycling (heat recovery and residue use)

* Data from April 2020 to September 2022 excludes Head Office of Mochida Pharmaceutical Co., Ltd.

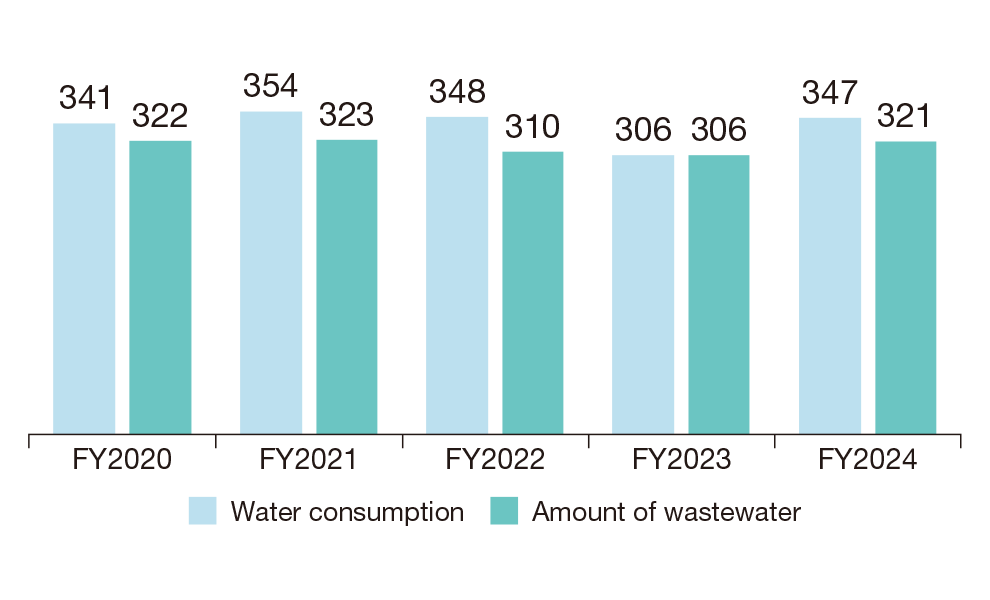

Water Resources and Water Quality

High quality water is essential for Mochida Pharmaceutical Group's business activities, especially its R&D and manufacturing activities. Mochida Pharmaceutical Group strives to comply with laws and regulations and water standards agreed with each local government and is working to use water resources efficiently and to manage wastewater properly. In addition, Mochida Pharmaceutical Plant Co., Ltd. has completely replaced the below ground drainage system with an above ground drainage system at its Head Office Plant to prevent soil contamination due to leakages. To ensure business continuity going forward, we will make effective use of finite water resources by managing our water consumption and amount of wastewater on an ongoing basis.

[ Trends of Water Consumption and Amount of Wastewater ] (thousand m3)

Sites covered:

Head Office, Gotemba site, Fujieda site and every other business site of Mochida Pharmaceutical Co., Ltd., Head Office Plant of Mochida Pharmaceutical Plant Co., Ltd., and Saitama Plant of Mochida Pharmaceutical Plant Co., Ltd. *

Water consumption:

Total of extraction of groundwater and water purchased from public water supply

* Data from April 2020 to September 2022 excludes Head Office of Mochida Pharmaceutical Co., Ltd.

Prevention of Air Pollution

In efforts to prevent air pollution, Mochida Pharmaceutical Group completed the switch from fuel oil to LNG and city gas in FY2019. This move reduced the Group's particulate matter, oxides of nitrogen and sulfur (NOx and SOx) emissions to zero. We will continue striving to comply with laws and regulations and the standards agreed with each local government.

Proper Management of Chemical Substances

The Gotemba and Fujieda sites, the Head Office Plant of Mochida Pharmaceutical Plant Co., Ltd., and the Saitama Plant of Mochida Pharmaceutical Plant Co., Ltd. fully recognize the impact that the chemical substances needed to develop and manufacture pharmaceuticals and healthcare products have on human health and the ecosystem, and they use and manage chemical substances properly.